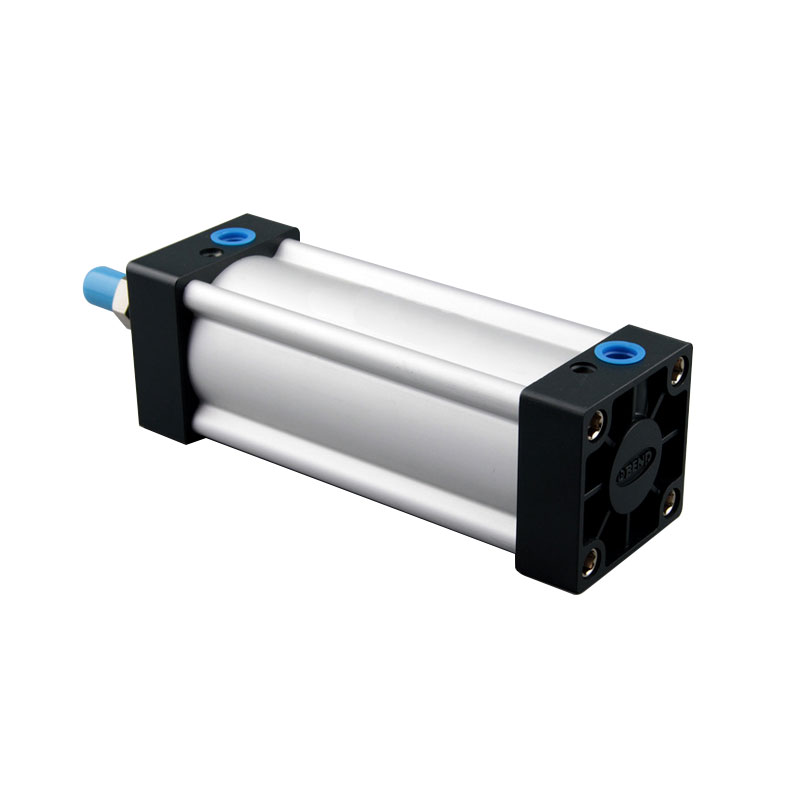

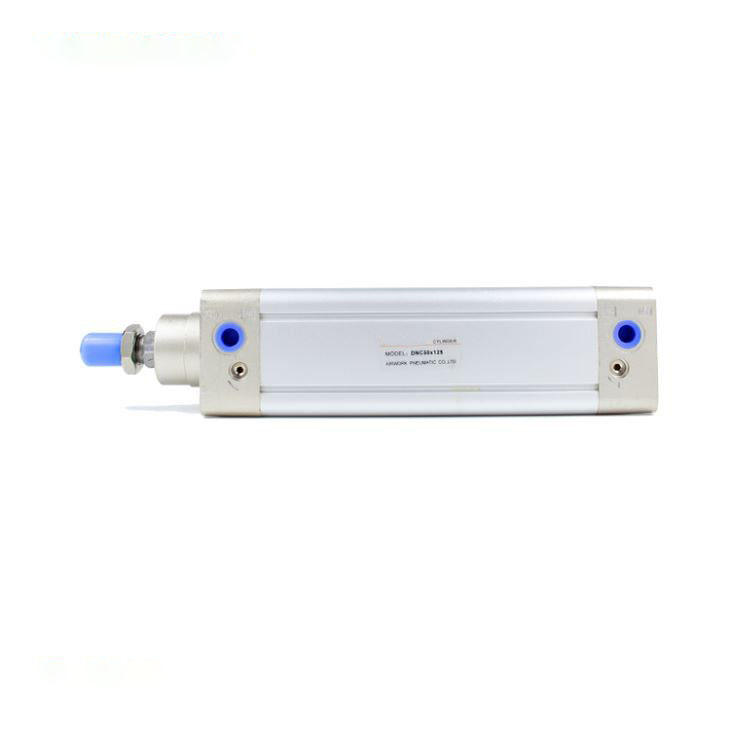

Standard Pneumatic Cylinder VDMA

- Brand:

- YUMO

- Place of Origin:

- China

- Size:

- 32, 40, 50, 63, 80, 100mm

- Operating Pressure:

- 1~10Bbar

- Working Environment Temperature:

- -20~+80°C

- Motion Pattern:

- Single-acting

Overview for VDMA Cylinder

VDMA ISO 6431 Cylinder is manufactured according to international standard ISO-VDMA specifications. VDMA 24562 Cylinder has no fastening rod and most parts can be replaced by each other. The fixed groove of embedded induction switch is designed on all four sides of the cylinder tube, and the installation position of the induction switch can be changed according to the actual use demand. The use of oil-containing alloy and special bearing bushing makes the piston rod have no need for lubrication.

The VDMA Cylinder is made of aluminum alloy and treated by alumina membrane, which is more wear resistant and corrosion resistant. Pipe bore PT and NPT thread type can be customized.

1. Configuration: with or without magnetic rings.

2. Type: double-acting, single-rod and double-rod.

3. Sealing ring material of Standard Cylinder: NBR

4. Special configuration according to requirements.

5. Main application industries: Food industry, machinery, medicine and other industries.

6. Product advantages: VDMA 24562 Cylinder adopt PUR seals, long service life, corrosion resistant design, built-in magnetic switch, lubricated with food grade grease.

Product Feature for VDMA Cylinder

RA/28000/M, RA/28300/M

Single-acting

Ø32~100mm

Comply with ISO 6431 Cylinder, VDMA 24562 Cylinder, and NFE49-003-1 standards

Polyurethane seals ensure effective low friction operation and long life

Standard installations are diversified in form

The magnetic piston ensures the flexibility of the control system