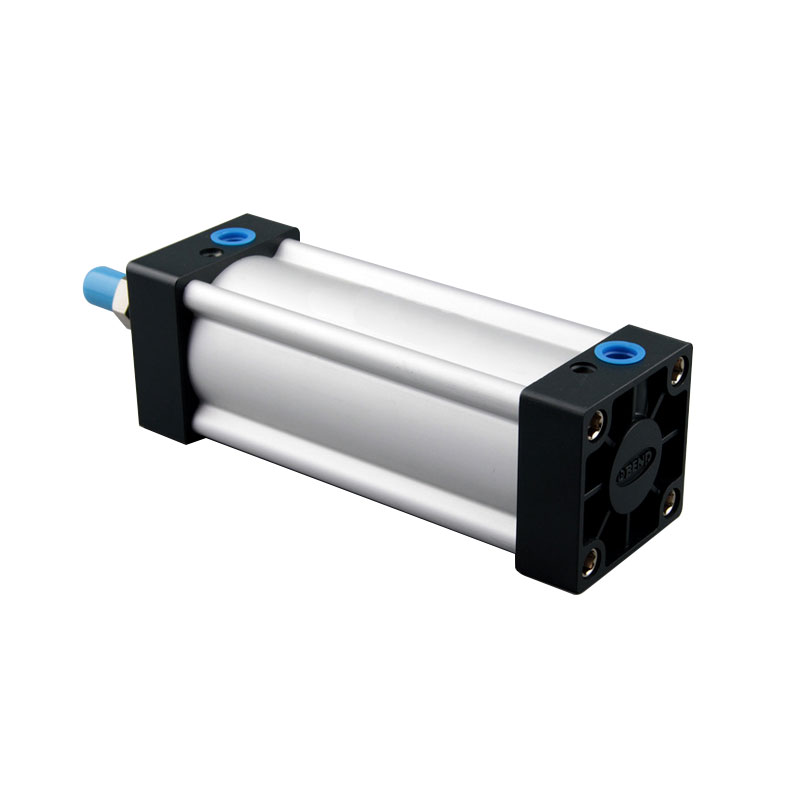

Standard Pneumatic Cylinder DNC

- Brand:

- YUMO

- Place of Origin:

- China

- Size:

- 32, 40, 50, 63, 80, 100, 125mm

- Operating Pressure:

- 0.1~1.0MPa

- Working Environment Temperature:

- -5~+70°C

- Speed:

- 50~800mm/s

- Motion Pattern:

- Double-acting

Overview for DNC Standard Cylinder

Seal ring of DNC Standard Cylinder adopts two Y-type one-way sealing structure, with compensation function, long service life and low starting pressure. It is square cylinder barrel, no rod, good corrosion resistance, buffer adjustment for cylinders; A variety of cylinder and cylinder installation accessories are available for customers to choose.

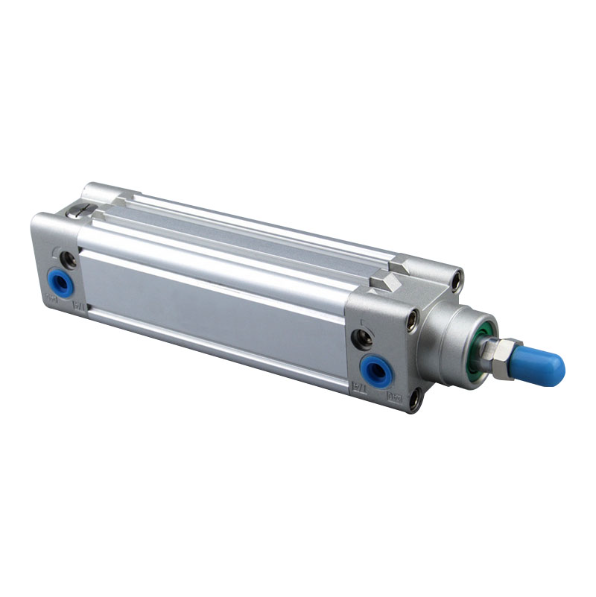

DNC Standard Cylinder can work normally without lubrication oil. The motion pattern is double-acting, piston type structure. Piston can be magnetic or not. The maximum operating pressure is 1.0MPa, the temperature range is -20~80℃, and the buffering mode is elastic buffer.

DNC ISO15552 Cylinder is highly standardized, its outline and installation dimensions are in line with international standards and many national standards, it is more convenient to replace different brands of cylinders. In the aspect of performance design, a series of functions can be extended by replacing related components, which is more convenient in practical application.

Product Features for DNC Standard Cylinder

DNC standard cylinder is beautiful in design, saving 11% of the space compared with the conventional cylinder.

There are two sensor grooves on the three sides of the ISO15552 Cylinder for position sensing.

The proximity sensors can be flush mounted in the sensor grooves and can be replaced by installing components without changing their position.

The installation accessories are various, so that the ISO15552 Cylinder can be installed in almost any place. The front and rear end covers are screwed directly on the cylinder barrel, and the hexagonal fixing screws with internal threads are used for the components installation.

The sensor groove can be sealed by the groove cover to make the cylinder surface smoother and protect the sensor cable, prevent foreign objects from entering the sensor groove.

In the case of higher speed or faster frequency, the auxiliary buffer ring helps to further absorb energy.