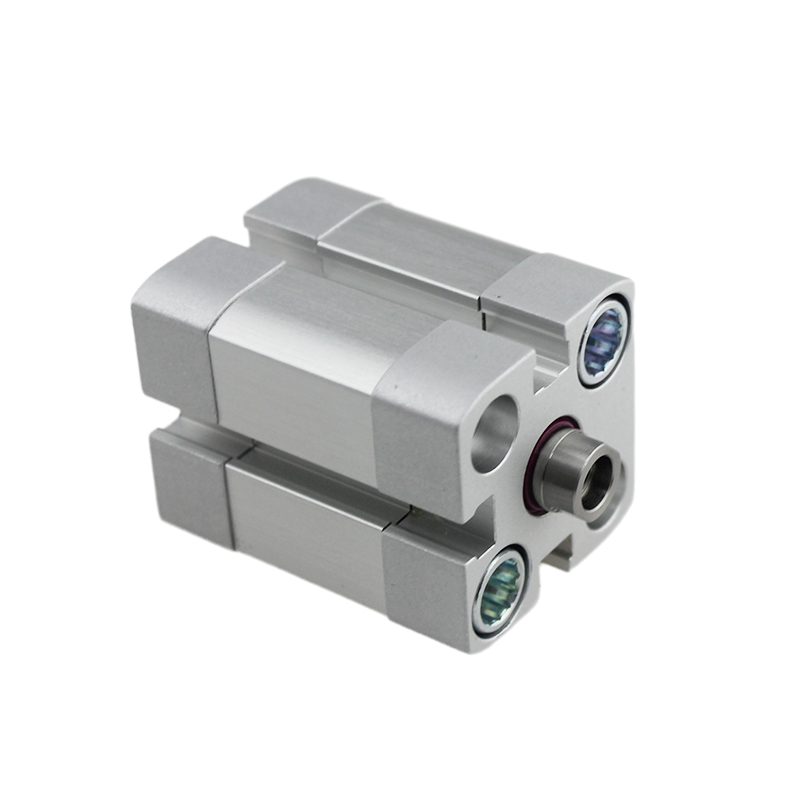

Festo Compact cylinder ADN-20-10-I-P-A New Automatic Controller accessories

- Model:

- ADN-20-10-I-P-A

- Brand:

- Festo

- MOQ:

- 2

- Place of Origin:

- China

- Type:

- Compact cylinder

- Certificate:

- CE ROHS ISO14644-1

- Application:

- Industrial production fields such as liquefied gas, urban natural gas, petroleum and chemical industry, as well as transportation fields such as automobiles and aviation

- Size:

- Compact

The main differences between Compact and standard cylinders are size, construction, application scenarios and price.

Compact cylinders are usually narrow and suitable for small space occasions, such as automation equipment and robots, and their width is about half that of standard cylinders, which makes thin cylinders more suitable for occasions where frequent movement is required or space is limited.

Standard cylinders are thicker and suitable for applications that require a larger output torque, such as punches, presses and hydraulic lifting platforms. Standard cylinders usually have a longer stroke and larger bore, providing higher load capacity and torque output.

The structure of the Compact cylinder is relatively simple, the use of piston structure, occupy small space, light weight, long service life, and the standard cylinder usually uses the piston rod and the piston axial split structure, has a high torque output, but occupies a large space.

The price of Compact cylinders is usually lower than that of standard cylinders because of its smaller size and simpler structure, while standard cylinders are also higher in price due to their larger size and complex structure.

In addition, the design stroke of the Compact cylinder is generally shorter, and the design stroke of the standard cylinder is longer.

| Technical Data | |

| Stroke | 10 mm |

| Piston diameter | 20 mm |

| Piston rod thread | M6 |

| Cushioning | Elastic cushioning rings/plates at both ends |

| Mounting position | optional |

| Conforms to standard | ISO 21287 |

| Piston-rod end | Female thread |

| Position detection | Via proximity switch |

| Symbol | 00991217 |

| Variants | Piston rod at one end |

| Operating pressure | 0.06 MPa ... 1 MPa |

| Operating pressure | 0.6 bar ... 10 bar |

| Mode of operation | Double-acting |

| Operating medium | Compressed air to ISO 8573-1:2010 [7:4:4] |

| Note on operating and pilot medium | Lubricated operation possible (in which case lubricated operation will always be required) |

| Corrosion resistance class CRC | 2 - Moderate corrosion stress |

| LABS (PWIS) conformity | VDMA24364-B1/B2-L |

| Cleanroom class | Class 6 according to ISO 14644-1 |

| Ambient temperature | -20 °C ... 80 °C |

| Impact energy in end positions | 0.2 J |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), return stroke | 141 N |

| Theoretical force at 0.6 MPa (6 bar, 87 psi), advance stroke | 188 N |

| Moving mass | 29 g |

| Product weight | 141 g |

| Type of mounting | Either: With through-hole Via female thread With accessories |

| Pneumatic connection | M5 |

| Note on materials | RoHS-compliant |

| Material collar screws | Steel |

| Material cover | Anodised wrought aluminium alloy |

| Material seals | TPE-U(PUR) |

| Material piston rod | High-alloy steel |

| Material cylinder barrel | Smooth-anodised wrought aluminium alloy |

| Dimension | 35.5 x 35.5 x 52.5mm |